A public-private partnership led by Hitachi Rail is developing the next-generation in battery train technology. The collaboration is creating a new battery pack that is lighter and smaller so it can be installed on commuter and suburban trains, while maintaining impressive power.

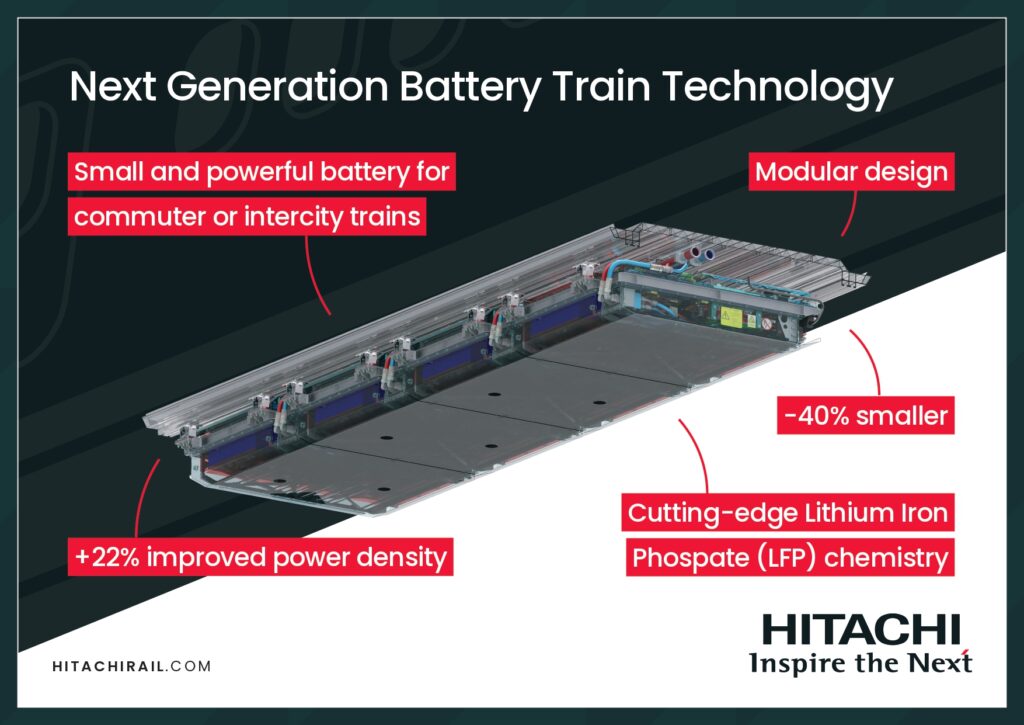

The battery pack that is being developed will build upon and complement the pioneering intercity battery technology that is currently being trialled on the Transpennine route and adapted for a regional train. The battery being developed will be 40% smaller and deliver a 22% improvement in energy density.

The ability to deliver impressive power from a smaller battery is achieved by using LFP (Lithium Iron Phosphate) battery chemistry. Collaborating with Sunderland-based battery supplier, Turntide Technologies, means Hitachi can bring the latest in automotive battery technology to the rail industry.

A smaller battery is essential to achieve inclusive design for lower floor trains and level access at platforms. Lower floors provide less space for batteries, making this project an important next step in promoting train accessibility.

A smaller and powerful battery can further reduce weight and make maintenance and the industrial retrofitting process easier.

DB ESG is supporting the project by leading the design of the battery enclosure to house the battery, including fire protection, cooling capability and electrical integration. Building on the knowledge gained in designing the enclosure for Hitachi’s intercity battery trial, the battery enclosure has been designed to make maintenance simpler and more efficient.

The Birmingham Centre for Railway Research and Education (BCRRE) at the University of Birmingham is optimising the design and usage of the battery, with railway simulations to validate the battery performance on representative UK routes, including railways in the North of England.

The partnership will allow BCRRE to further enhance the capability of their existing railway simulator, improving the knowledge and skills base for future students and graduates at the university.

The £1.4 million R&D comprises of match funding from both the private sector and public sector, with Innovate UK co-funding the project to encourage new UK battery innovation, inclusivity in the railway and combined with enabling new skills and experience at University of Birmingham.

Koji Agatsuma, chief technology officer Vehicles, Hitachi Rail said: “The acceleration of battery innovation is incredible. This is why at Hitachi, we use our expertise from Italy, Japan, and the UK to ensure our partners remain at the forefront of battery technology.

“This continuous improvement means we are always working on the next generation of smaller and more powerful batteries to reduce cost on railways by negating electrification infrastructure spend or removing diesel engines entirely.

“Meanwhile our partnership with Innovate UK and University of Birmingham means Hitachi is playing an active role in growing new skills in the British battery sector, while also developing battery solutions that can be used on railways across the globe.”

This project draws upon Hitachi’s global expertise which includes delivering the world’s first passenger battery train in Japan, and rolling out the Masaccio, Europe’s first battery hybrid train in Italy in 2022.

The development of this battery is an important step for the rail industry both home and abroad. Using its expertise in the UK, Japan and Italy, Hitachi Rail has an ambition to install this battery on trains around the world, potentially creating a UK export and improving energy efficiency.

Image credit: Hitachi Rail