Engineers have found a new way to produce the “wonder material” Graphene that could finally allow it to make the most of its potential.

When it was discovered by creating a single layer of carbon atoms in 2004, scientists hailed the material as a potential revolution. It is extremely conductive and very strong, and experts said it could transform everything from energy storage to medical devices and personal electronics.

But that potential has never fully been realised. That is in part because it is hard to make cleanly and at scale.

One of the problems is that it is difficult to make cleanly and without impurities. But researchers say the new process allows graphene to be made in a way that is reducible and clean.

They did so by acting on a finding that the quality of the graphene was linked to oxygen. If there is even a small part of oxygen around, then it drastically affects the growth rate of the graphene and means that it might not be possible to use it.

“We show that eliminating virtually all oxygen from the growth process is the key to achieving reproducible, high-quality CVD graphene synthesis,” said senior author James Hone, from Columbia University. “This is a milestone towards large-scale production of graphene.”

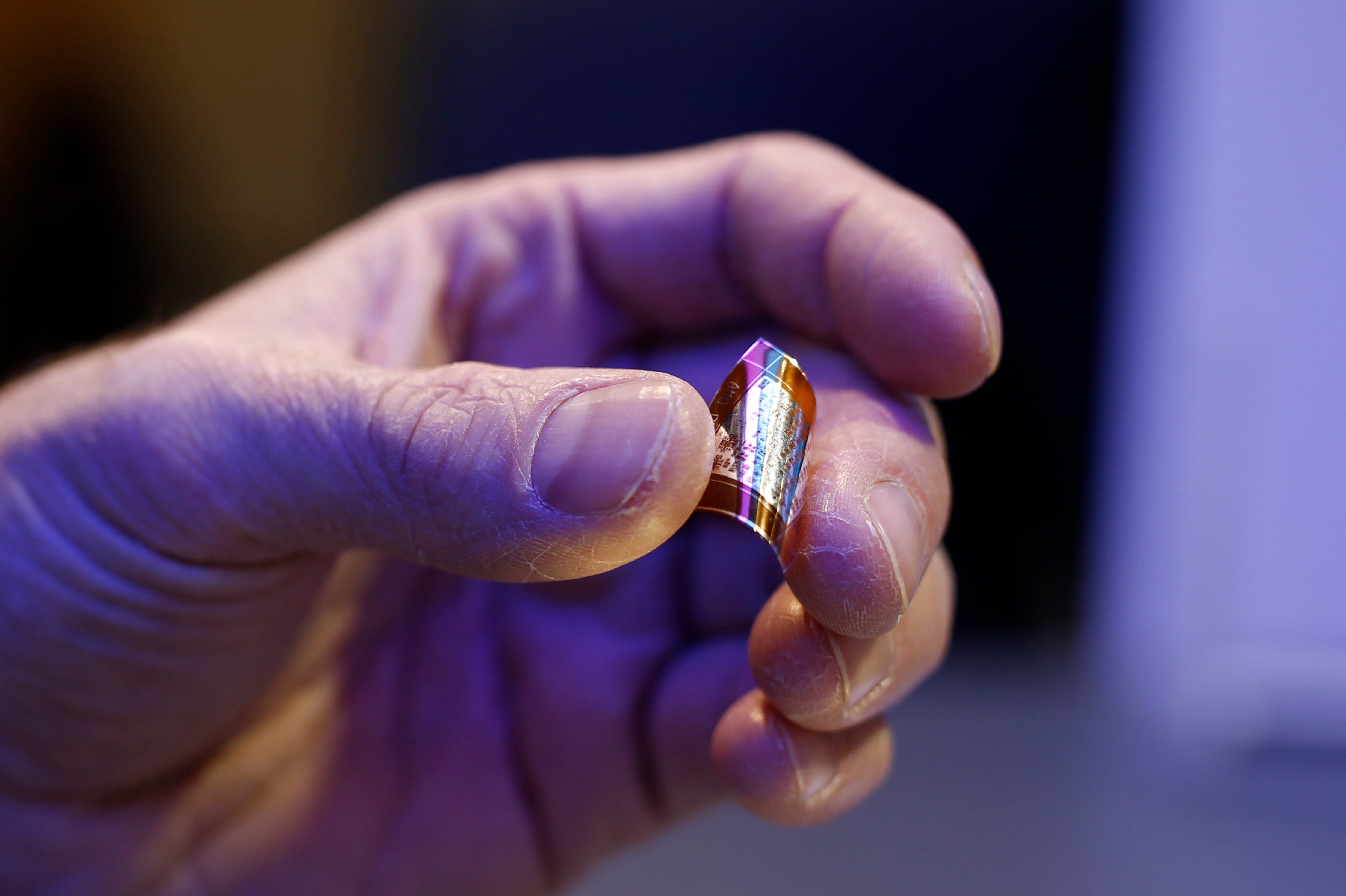

Engineers have traditionally made graphene in two ways. The first uses tape to peel away layers of a piece of graphite until it is thin enough to be used as graphene – which produces clean samples, but at a tiny scale that makes them impossible to use industrially.

The other allows for much more production and is known as CVD growth. It involves passing a carbon-containing gas such as methane over a copper surface at incredibly high temperatures, which leads the methane to break apart and forces the carbon atoms to rearrange into a layer of graphene.

That allows them to be made up to the size of meters across. But they have also suffered from problems with being dependable in their quality.

Researchers had already found that any oxygen in that process would slow it down or even etch the graphene away. Since then, engineers have been trying to build new systems that could control the oxygen and stop it undermining th eprocess.

Now scientists say they have dramatically improved that process, allowing the graphene to grow faster and dependably. They found that the graphene produced also showed all the necessary behaviours that could allow for it to be used at scale.

The work is reported in a new paper, ‘Reproducible graphene synthesis by oxygen-free chemical vapor deposition’, published in the journal Nature.